Injection Molding Automation Solution

Contact us for professional advice on robot automation solutions

Contact us for professional advice on robot automation solutions

Contact us for professional advice on robot automation solutions

Contact us for professional advice on robot automation solutions

The workshop layout is narrow, the space is limited, the robot selection arm span is not easy to touch the equipment, and the accuracy is not matched, which affects the production.

The professional team of RBTC can accurately select the robot configuration with appropriate arm span and matching accuracy according to your field data.Engineers will go deeper into the site, through the whole process of installation and commissioning and simulation production, to avoid problems in advance, to ensure that the program can be used and used efficiently.

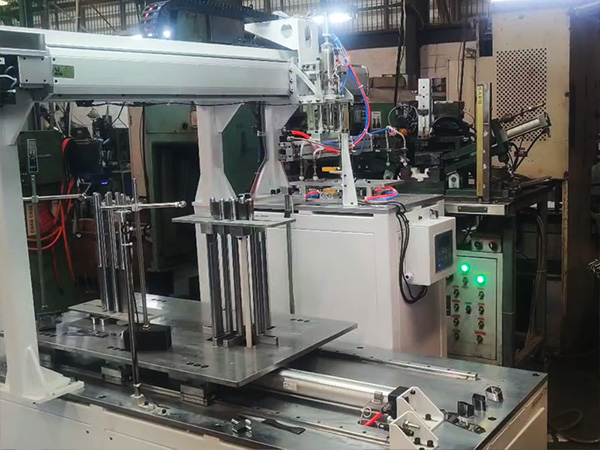

The production line process is complex, the workshop contains stamping, injection molding, palletizing and other processes, and the rhythm of multi-equipment connection is not matched.

The RBTC professional team can sort out the production line process flow, and customize robots based on the operation accuracy, load, and cycle time requirements of each link.Engineers go deep into the site to build a "robot-equipment" linkage system, optimize the material transfer path through simulation production, and realize the seamless connection of multi-process robots.

Standardized robots are "one-size-fits-all", have low compatibility with non-standard production lines, and have a high rate of equipment idleness.

The RBTC team can provide on-site mapping and, based on the size of the production line, processing path and precision requirements, load appropriate auxiliary equipment for the robot. Engineers calibrate the connection between the robot and the production line on-site, verify the processing trajectory of the workpiece through simulation, and ensure that the robot is 100% compatible with the production line.

24 hours of continuous execution of welding, assembly, handling and other high-precision repetitive operations, widely used in automotive, electronic manufacturing, greatly improve production efficiency and stability.

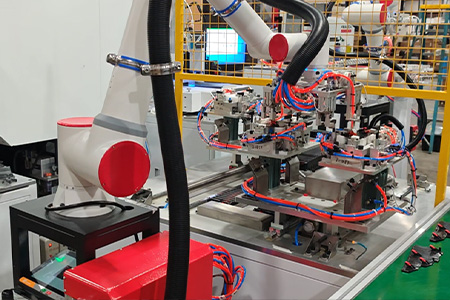

Specifically designed for injection molding production, it automatically completes processes such as part removal, insert, and blanking, reducing the risk of manual contact with high-temperature molds while ensuring the accuracy of injection molded part removal and production rhythm.

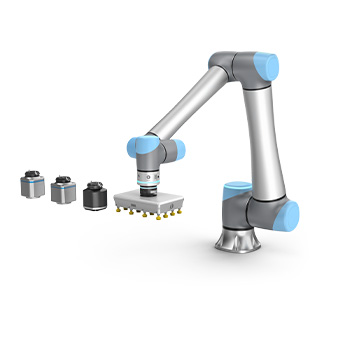

With human-machine cooperative safety function, it can cooperate with workers to complete flexible operations such as sorting and screw tightening at close distance, without complex protection, and is suitable for small-batch and multi-variety production needs.

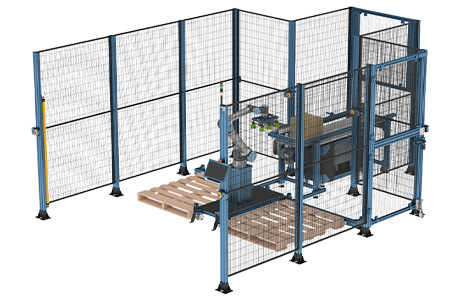

Efficiently complete the automatic stacking and stacking of cartons, pallet and other materials, replace manual high-intensity labor, accurately control the height and stability of palletizing, suitable for logistics, storage, food and other industries.

Robot Arm Range:500mm-3500mm

Load Range:1kg-500kg

Positioning Accuracy Range:±0.01mm-±0.5mm

Control System:Drives hardware operation, provides real-time feedback and error correction, and is compatible with external devices (such as injection molding machines).

Programming Logic:Adjust operation parameters and running cycles according to the production line process flow, such as welding, palletizing, spraying, injection molding, stamping, CNC loading and unloading, etc.

Integrated customization includes the linkage of EOAT (End-of-Arm Tooling) and non-standard customized equipment, along with the customization of production line layout and safety protection (such as fences and sensors).

RBTC will analyze the data or samples you provide to ensure that your requirements are met.

We provide you with an initial design plan, covering robot selection, core parameters and preliminary layout.

Communicate with you to adjust the design plan. If necessary, on-site investigation services can be provided to ensure that the plan is in line with the actual scene of the workshop.

After the design plan is confirmed, we will provide you with a detailed quotation, including the costs of equipment, services, etc.

3D simulation optimizes the robot's trajectory and production layout to avoid spatial conflicts and efficiency bottlenecks in advance.

Complete production assembly design, equipment debugging and functional testing to ensure hardware compatibility.

Write programs based on the actual production requirements of the project, and synchronously debug the program logic and the coordination of equipment operation.

On-site installation and commissioning services are available, and offline robot operation training is also carried out to ensure that your team can use it independently.

A solid guarantee from "being able to do" to "doing well"

Core members have rich industry experience and have served over 1,000 + cases

A service closed loop from "delivery" to "lifetime service", with a 24-hour response

Looking for industrial robot solutions or automation support?

RBTC provides end-to-end services including robot selection, application evaluation, system integration, and project implementation.

Contact our engineering team to discuss your production requirements and explore a suitable automation solution.

+86-13826981851