Easy Operation

Easy use of robotsEquipped with graphical programming and drag-and-drop teaching.

Manual welding often struggles to maintain consistent weld quality, stable cycle times, and workforce availability—especially in high-volume or precision-driven manufacturing environments.

As production scales and quality requirements increase, these variations gradually turn into long-term operational risks.

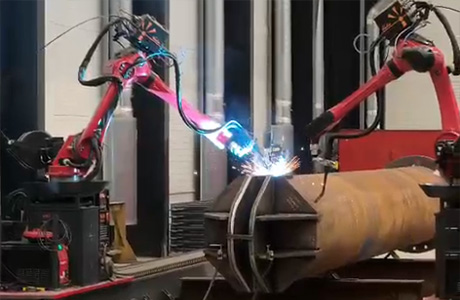

RBTC provides industrial robot welding automation solutions, combining industrial robots with application-oriented system integration. Our solutions are designed to help manufacturers achieve stable weld quality, predictable production output, and long-term operational consistency, rather than short-term efficiency gains.

RBTC works as an application-focused industrial robot and automation solution provider, supporting robotic welding projects from system design to on-site commissioning under real factory conditions.

Equipped with graphical programming and drag-and-drop teaching.

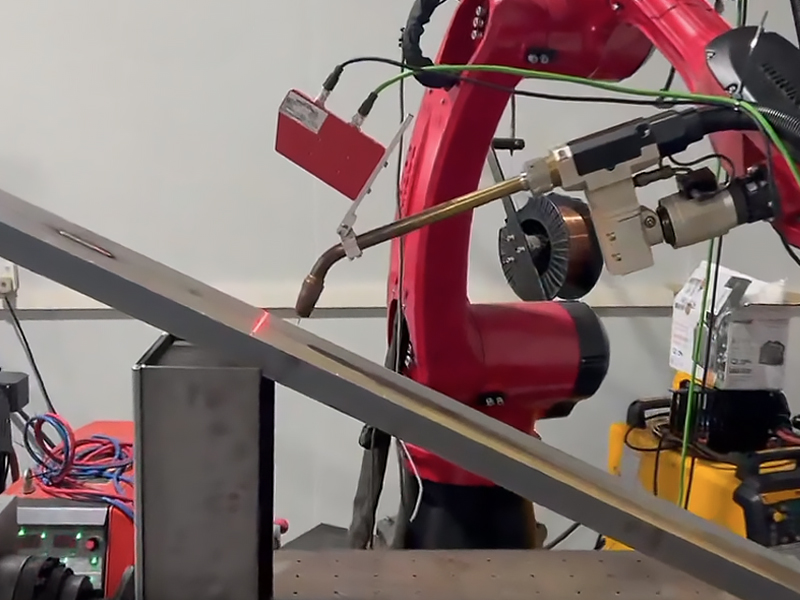

Featuring point recording, welder assistance, and weld visual positioning.

Customized ground rails can be added for easy movement, supporting quick switching between multi-station and multi-position welding scenarios.

RBTC robotic welding automation solutions support a wide range of industrial welding processes, including:

Suitable for structural steel, automotive components, and general metal fabrication.

Applied in precision welding scenarios requiring clean seams and controlled heat input.

Commonly used in automotive body assembly and sheet metal processing

Each robotic welding system is configured based on actual production conditions such as material type, joint geometry, required weld quality, and production takt time.

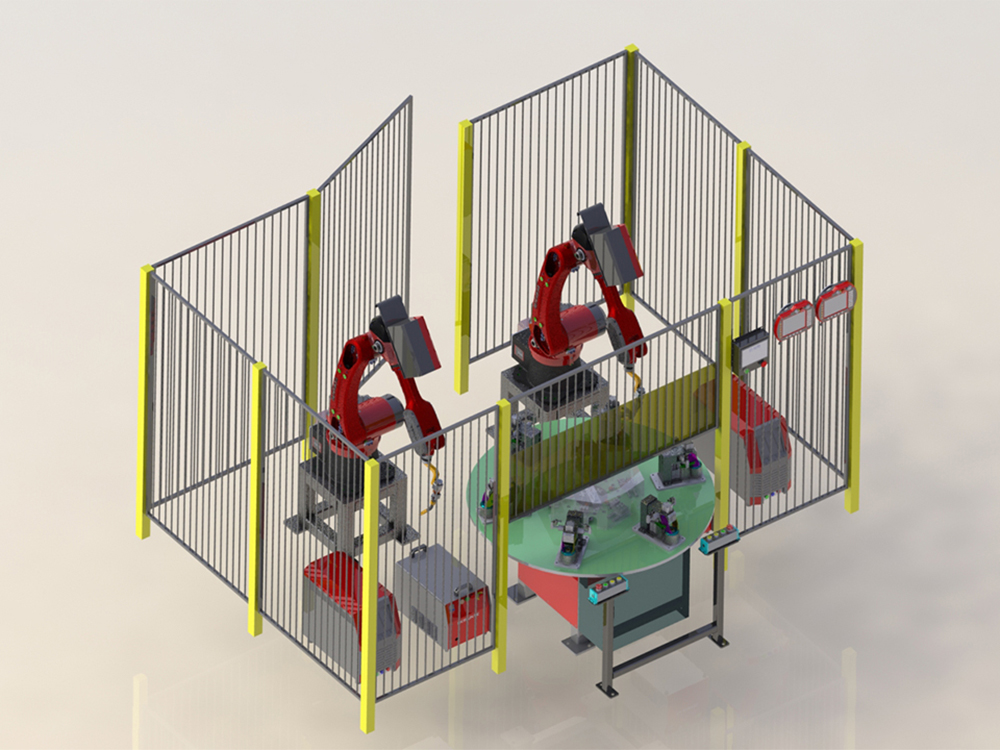

A industrial robotic welding automation system includes:

Six-axis industrial robot provides flexible motion paths and stable repeatability for complex welding trajectories.

Selected according to welding process requirements to ensure arc stability and consistent penetration.

Configured based on material thickness, joint type, and production speed.

Improve workpiece accessibility and ensure consistent welding accuracy.

Including safety fencing, interlocks, and centralized control interfaces.

RBTC focuses on system-level integration, ensuring all components operate reliably as a complete robotic welding cell.

Every welding application is different. RBTC provides application-oriented customization instead of one-size-fits-all systems, including:

Optimizing motion trajectories for complex weld joint geometries to ensure consistent weld bead formation.

Supporting seam tracking or vision systems.

Offering custom positioners, rotary tables, fixtures, and other tooling.

Integrating with existing conveyor lines or CNC equipment.

Adapting to high‑temperature, dusty, or continuous‑operation environments.

Providing international on‑site installation and commissioning services

This approach ensures the robotic welding system fits actual production needs without unnecessary complexity.

Looking for industrial robot solutions or automation support?

RBTC provides end-to-end services including robot selection, application evaluation, system integration, and project implementation.

Contact our engineering team to discuss your production requirements and explore a suitable automation solution.

+86-13826981851