Home / All

News

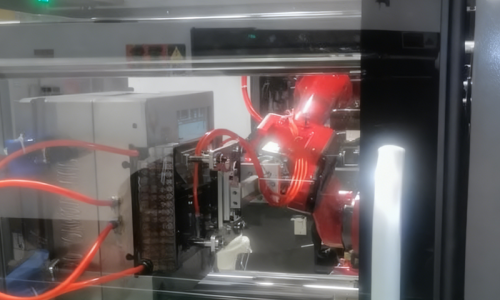

- CNC Loading & Unloading Robot Commissioning ProjectTo ensure smooth CNC loading & unloading commissioning, RBTC formed an exclusive technical team for on-site commissioning in Indonesia.Dec 23,2025

- Automation Upgrade of European Injection Molding FactoryWith the upgrading and high-end development of global industries such as automobiles, electronics, medical devices, and home appliances, the market demand for precision plastic parts continues to expand, putting pressure on plastic parts factories of European customers to upgrade their products.Nov 20,2025

- 50kg Fertilizer Bag Automatic Palletizing SolutionUnder the traditional manual palletizing mode, factories are confronted with production predicaments under high risks and heavy burdens.Nov 20,2025

- Automation Solution for Automotive Parts Welding RobotsWelding is one of the four core processes in automotive production, directly determining the safety and stability of the vehicle body structure.Nov 19,2025

- A 48-hour "Quest for Opportunities" spanning thousands of milesAfter comparing 8 brands from 3 countries, a customer embarked on a 48-hour express journey across thousands of miles from November 3rd to 4th, heading straight for RBTC to seek a solution.Nov 11,2025

- Injection molding robot embedding and removal projectA Southeast Asian enterprise specializing in plastic product manufacturing, confronted with issues such as the continuous rise in local labor costs and insufficient product precision and stability, proactively reached out to the RBTC team, hoping to achieve an automated upgrade in the production process by introducing IMM robot for injection molding, embedding, and removal operations.Jul 2,2025

- Automated loading and unloading for bottle preform blow moldingIn the current era when the plastic processing industry is booming and competition is becoming increasingly fierce, a manufacturer specializing in preform production, in order to seize the market opportunity, has contacted the RBTC team and decided to introduce industrial robots for blow molding loading and unloading operations. Customers expect to bring about a transformation in production through our cost-effective robot solutions and simple operation control.Mar 11,2025

- The tableware industry in South America achieves automation upgrade with industrial robots.In the course of the tableware industry's automation drive, a South American client adopted our industrial robots for stamping operations to boost efficiency, cut costs, and enhance quality. Our team provided a solution that is cost - effective and easy to operate. Through collaborative efforts, the project was smoothly completed, resulting in significant improvements in production efficiency, product quality, and safety safeguards, and winning the client's high recognition.Nov 20,2024

Want to achieve automation but don't know where to start?

Our consultants can conduct an automation assessment for your factory, precisely determine the suitable processes, save labor and time costs, improve production efficiency and quality, and enable you to get a higher return on investment.Contact Person

- Name:

- Tommy

- Tel:

+86-13826981851

- Email:

- Tommy@iroboticplus.com

- WhatsApp:

- 8613826981851

- Address:

- Room 102, No. 30, Hengfeng 2nd Road, Daguo, Changping Town, Dongguan City, Guangdong Province